Oxford Sigma and Singapore University of Technology and Design are collaborating on research to rapidly design radiation-tough multi-component tungsten alloys, focusing on materials suited for nuclear fusion energy systems.

The realisation of fusion energy is dependent on the success of the structural and functional materials’ performance over the lifetime of the reactor. The materials selection for fusion is still under development. The performance and reliability of structural, heat sink and plasma facing materials for In-Vessel Components (IVCs) is one major outstanding challenge for the successful development and deployment of fusion energy as a future energy source. The IVC divertor and first-wall tiles are the most thermally loaded in-vessel components in a fusion reactor. These tiles experience high heat fluxes (10 – 20 MW/m2) by intense plasma bombardment (deuterium, tritium, and helium), are damaged by neutron radiation (1 – 50 dpa), and are heated internally via nuclear decays (~10 MW/m3) induced by neutron irradiation. The combination of these environmental conditions creates a paramount engineering challenge that requires the development of durable, robust, and precise materials for the tiles. So far tungsten has been the leading material candidate for these materials, however, it has challenges with radiation-induced embrittlement and oxidisation behaviour under accident scenarios.

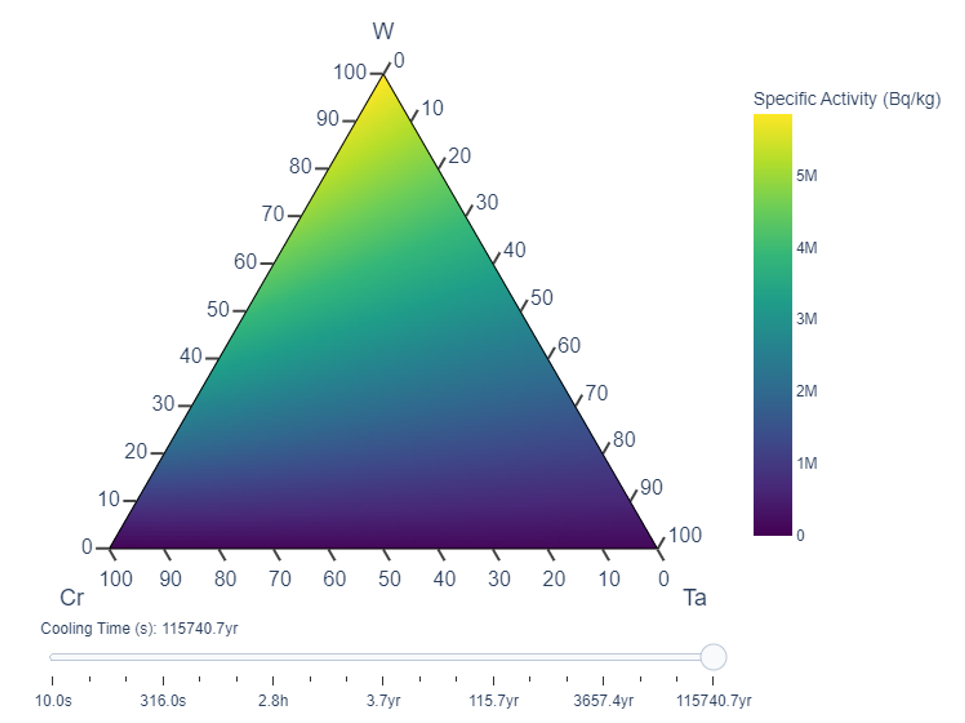

Oxford Sigma and Singapore University of Technology and Design have teamed up to rapidly develop novel tungsten-based alloys to identify new compositions that would reduce the effects of radiation damage and oxidisation during accident scenarios. This research program will utilise the extensive UK fusion user facilities to characterise and develop these newly identified material systems. A key development path is to understand the effects of, and possible mitigation strategies against, liquid metal corrosion on these novel materials; the liquid metals that are of interest are lithium, lead-lithium, and lithium-tin due to their breeding and cooling properties.

Oxford Sigma will be providing its expertise in fusion materials development, experience in research and development of material systems, and its industrial network. The company works with governments, national laboratories, private fusion industry, and public fusion programs who are all pursuing the acceleration of fusion energy to tackle energy security and the climate change challenges that the world faces.

“Oxford Sigma is striving to provide genuine novel material solutions for the extreme regions within fusion reactors. By teaming up together, Oxford Sigma and Singapore University of Technology and Design are combining our joint expertise in silicon advanced manufacturing and fusion energy materials development. Our collaboration enables the generation of rapid innovation that this industry needs.” ~ Dr Thomas Davis, CTO Oxford Sigma.

The Singapore University of Technology and Design (SUTD) was established to advance knowledge and nurture technically grounded leaders and innovators to serve societal needs, with a focus on Design, through an integrated multi-disciplinary curriculum and research.

In the Advanced Nuclear Materials for Fission and Fusion Reactors subproject within the ACTAlab group at SUTD, the university is investigating new materials for fission and fusion reactors. Radiation damage and the subsequent effects in materials are a major and unavoidable consideration for the design of components for a nuclear reactor, be it fission or fusion. Safe and reliable reactor components depend on radiation tolerant materials.

“The extreme conditions of a fusion reactor require advanced materials solutions. In this project we aim to accelerate the screening of new, radiation tolerant materials, by applying high throughput characterisation and rapid alloy prototyping techniques. By working with Oxford Sigma, we hope to develop industrially relevant solutions to engineering challenges.” ~ Dr Matthew Lloyd, Research Fellow at SUTD.

Oxford Sigma tackles energy security and climate change by accelerating the development of fusion and advanced nuclear energy. The company’s aim is to develop innovative nuclear technology to withstand extreme environments, provide nuclear materials expertise, and advise the advanced nuclear and fusion energy industries in their quest to achieve commercialisation.

Please do get in touch at [email protected]